Key attribute

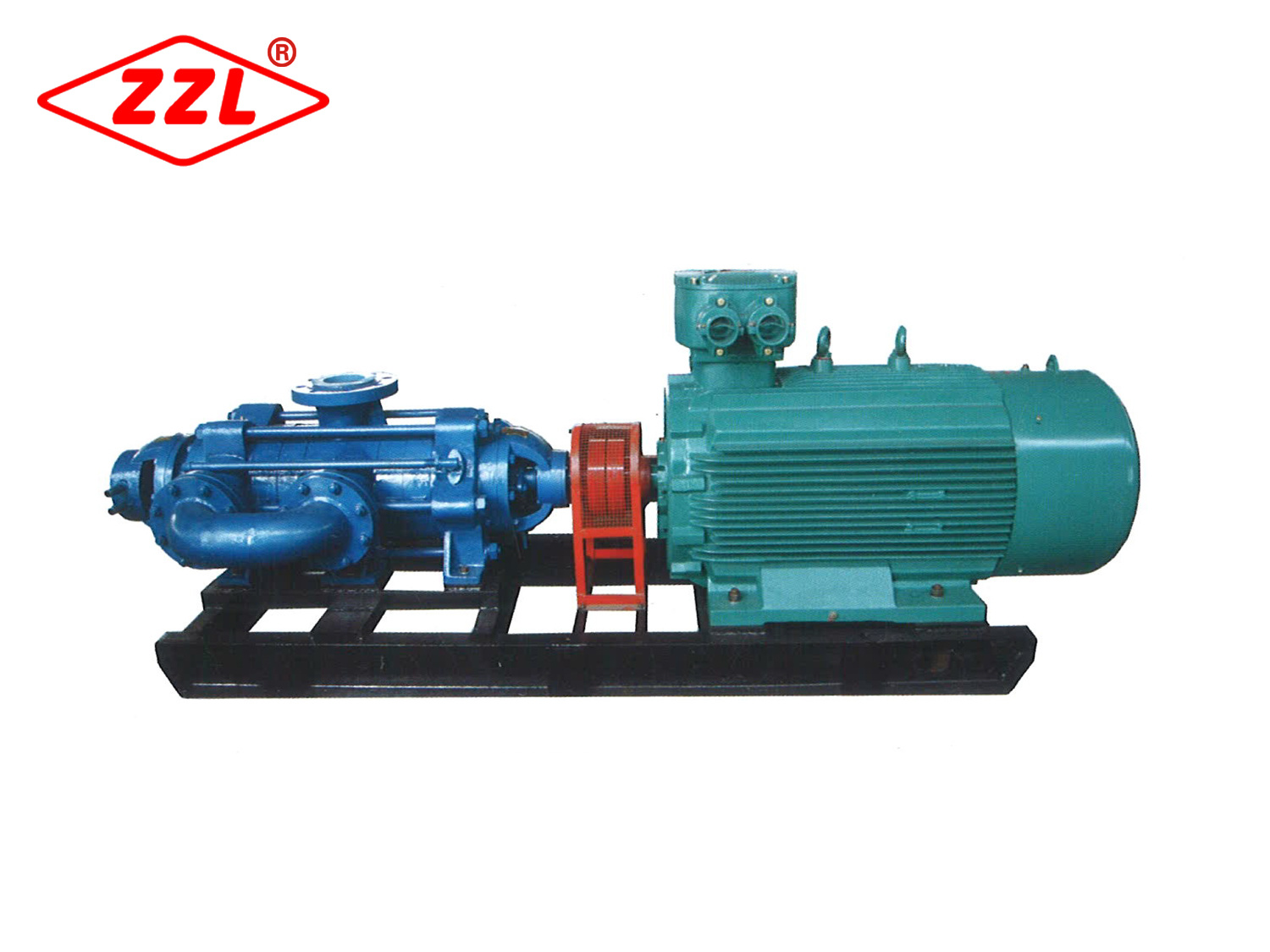

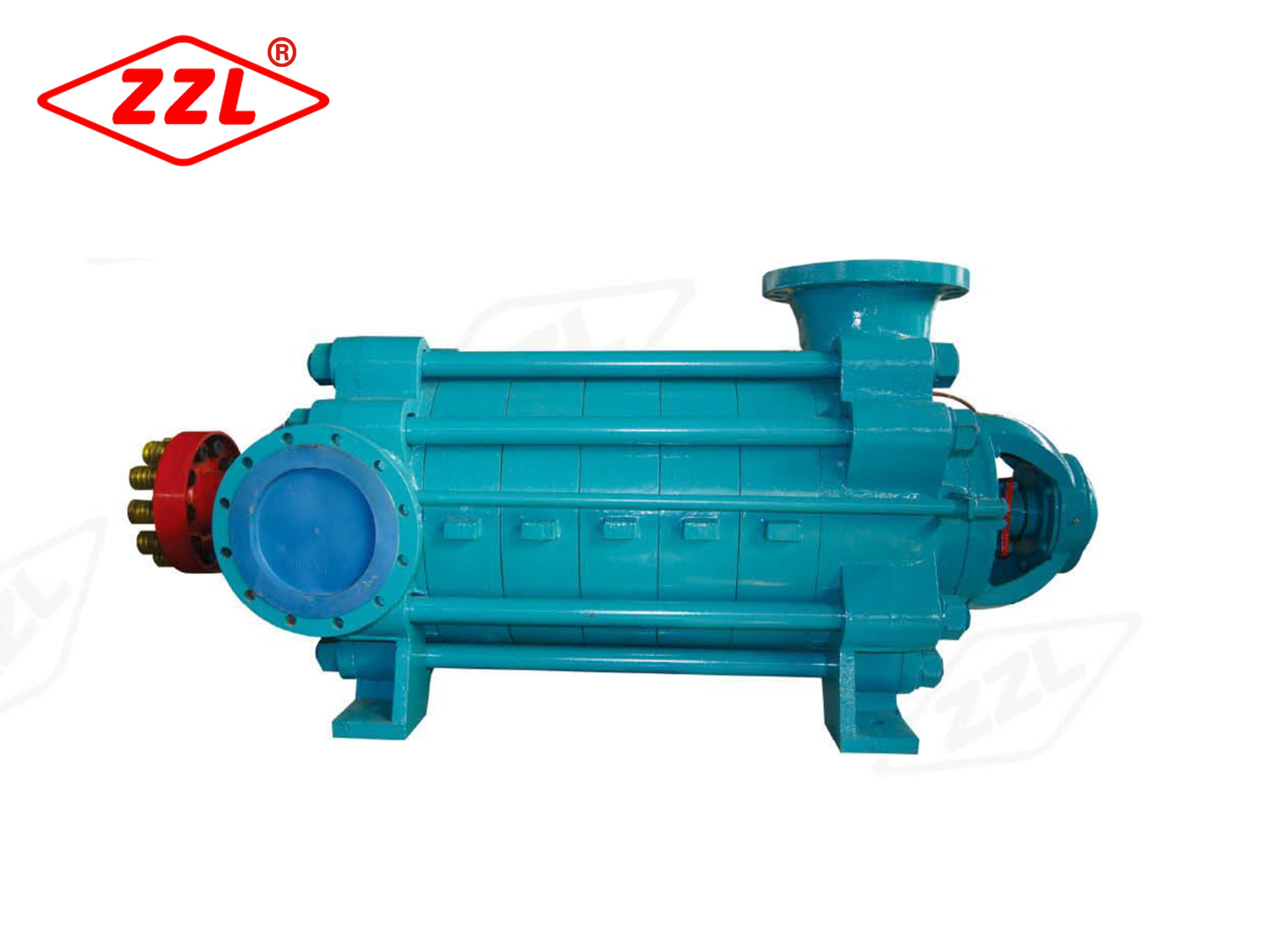

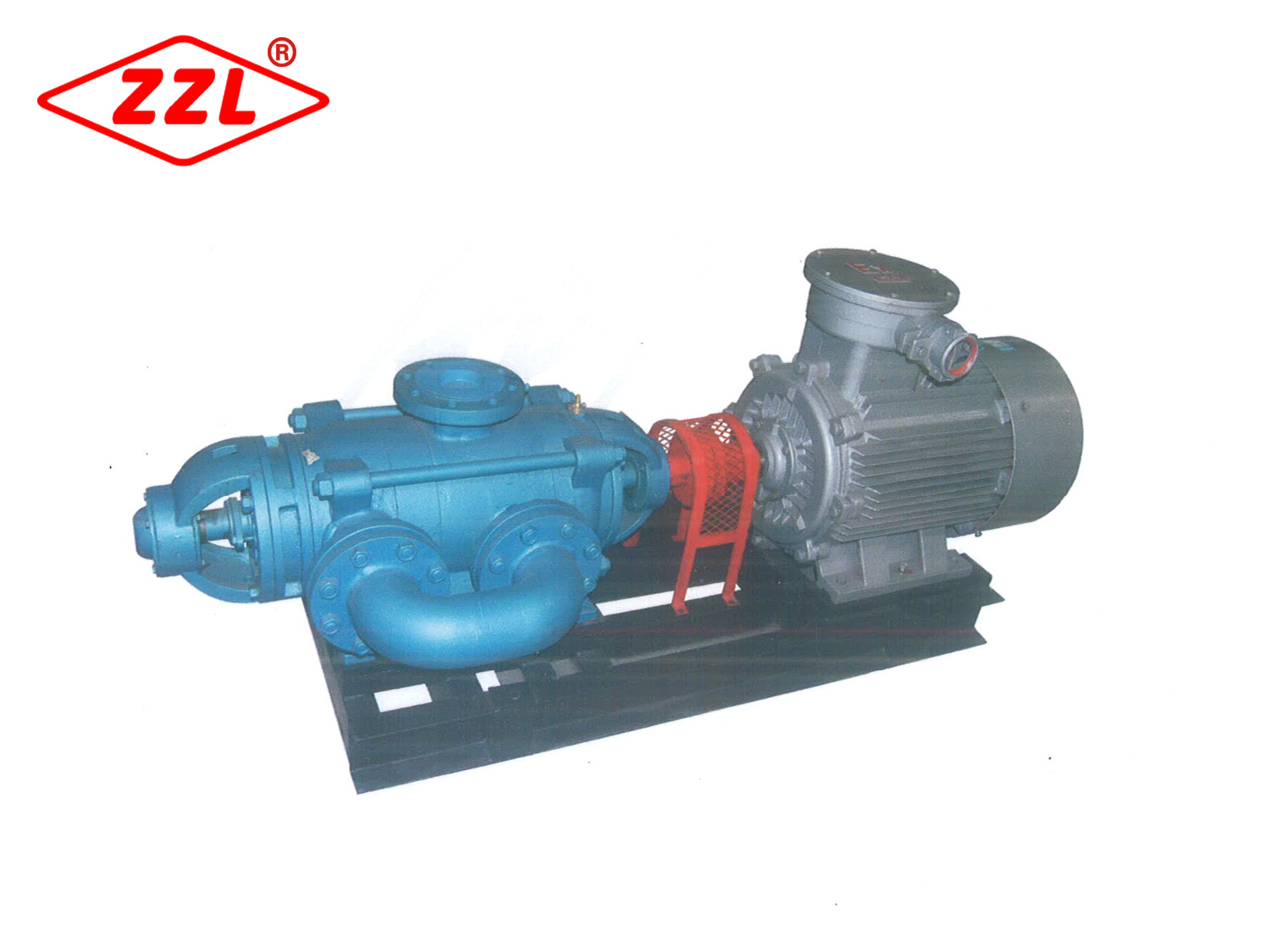

DG type high pressure boiler feed water pump is a kind of industrial boiler water supply and drainage, cooling water transmission device.

Product Introduction

DG type horizontal multi-stage boiler feed water pump adopts hydraulic model, so DG type boiler feed water pump has high efficiency and wide performance range, which better meets the requirements of users. Used to replace the old type of GC centrifugal pump, the structure of the horizontal, multi-stage pump segmented, and thus safe operation, stable, low noise, long life, easy installation and maintenance. This type of pump is especially suitable for industrial boiler water supply and drainage, cooling water transportation, etc. It can also be used to transport hot water, oil, corrosive media, etc. by changing the material, sealing form and increasing the cooling system. It is widely used in petrochemical, hot water circulation, environmental protection industry, pure water transportation and other industries.

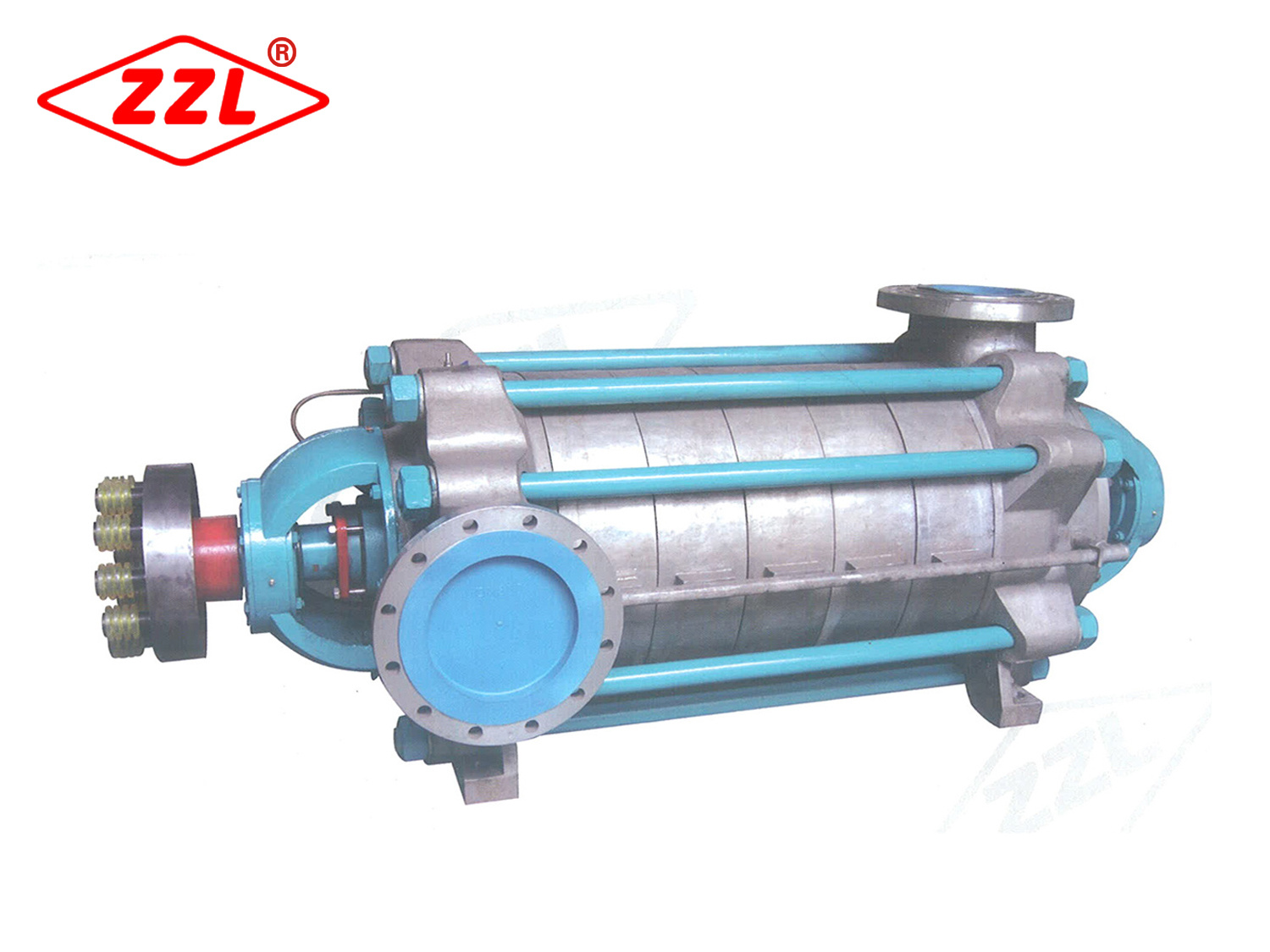

Structure Description

The pump housing part is mainly composed of the bearing body, the front section, the middle section, the rear section, the guide vane and other bolts to connect the whole, the front section of the suction inlet center line and the horizontal vertical, can also be a horizontal line. After the spit out midline and horizontal vertical, can also be a horizontal line.

The rotor part is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The parts on the shaft are fastened with a flat key and a sleeve nut to make them integral with the shaft. The entire rotor is supported on the pump casing by bearings at both ends, and the impeller in the rotor part is based on the number of stages of the pump. The rotor is driven by a motor, and the pump rotates clockwise when viewed from the motor end.

This type of pump uses rolling bearings, depending on the model, do not bear the axial force, the pump should be allowed to run the rotor part in the pump housing axial movement, can not use radial ball bearings. The bearing is lubricated with calcium-based butter.

The front, middle and rear sections of the pump are sealed with molybdenum disulfide grease. The rotor parts and the fixed parts are sealed by sealing rings, guide vane sleeves, packing, etc. When the degree of wear of the sealing rings and guide vane sleeves has affected the work and performance of the pump, it should be replaced in time.

The pump uses packing seal or mechanical seal, in use, packing and mechanical seal position security to be correct, packing and mechanical seal tightness must be appropriate, to fluid can be a drop of a drop of seepage is appropriate.

DG type multi-stage boiler feed water pump with medium and low pressure and sub-high pressure

Category:

TAG:

TRUSTED SERVICES

We Trusted Our Customers

24/7 SUPPORT

EXPERT TEAM

Professional R&D and production team

Technical patents

Leave your contact information to get a free product quote

Related Products

MDP, MDSP, DFP, DFSP series self-balancing multistage centrifugal pump

MDP, DFP, MDSP, DFSP self-balancing multistage centrifugal pump is a multistage

MD multistage centrifugal pump

D type coal mine with multi-stage centrifugal pump.

MD(P) self-balancing wear-resistant multistage centrifugal pump

MD(P) self-balancing wear-resistant multi-stage pump is a single-suction multi-stage structure.

DF, DFS type corrosion-resistant multistage centrifugal pump

DF-type corrosion-resistant multistage pump is a single-suction multistage segmented centrifugal pump.