Key attribute

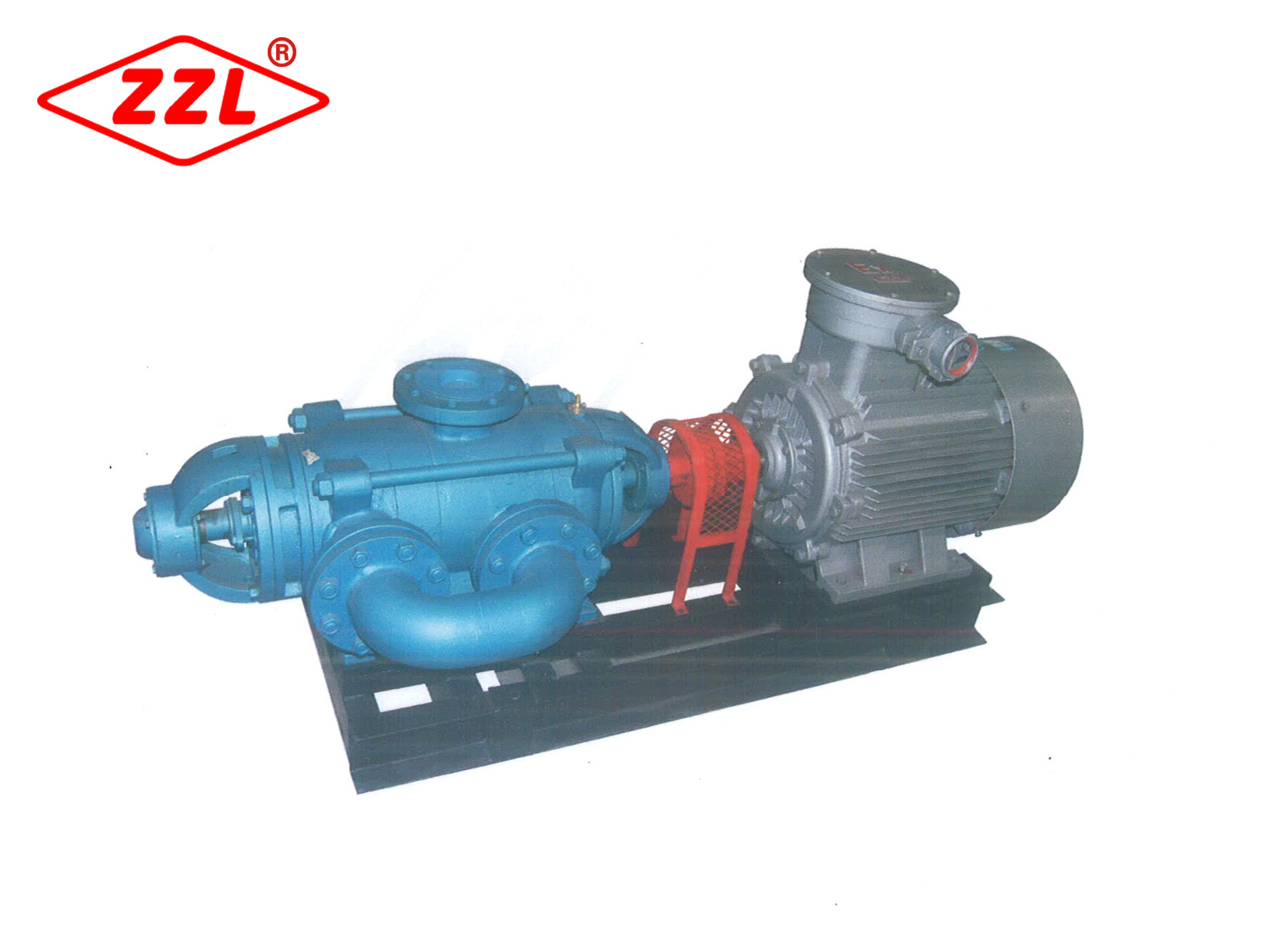

Chemical process pump is the general name of various pumps in the chemical production process. The configuration of the pump has high power, high speed, small overall size, simple structure, easy maintenance, but high temperature, easy to wear, and large maintenance coefficient. Therefore, the maintenance and maintenance of the pump is relatively difficult. In order to reduce the number of overhauls, the maintenance and maintenance of the equipment must be done well.

Working conditions

Suitable for conveying neutral or corrosive, clean or containing solid particles, low temperature or high temperature liquid medium.

Working pressure: maximum 2.5Mpa;

Working medium temperature:-70 ℃-180 ℃;

Maximum flow: 2000 m3/h; Maximum lift: 160m;

Speed: 1450r/min and 2900r/min;

Supporting motor maximum power: 315Kw.

Advantages

1. The impeller can be closed, semi-open and open. Can transport clean, containing particles, containing a small amount of gas medium. Can also transport high temperature, low temperature, strong corrosive medium. The impeller is provided with a balance hole and a corrosion-resistant ring to balance the axial force.

2. The pump body and the bearing frame are connected by the middle connecting section. According to different working conditions, the intermediate connecting section can be made of different materials to avoid serious corrosion of the bearing frame and bearing when conveying strong corrosive medium. At the same time, the middle connecting section is provided with a water-cooled cavity, which passes through the cooling circulating water to block the high temperature medium from transmitting the high temperature to the bearing.

3. The sealing form can adopt packing seal, single and double mechanical seal, and container type single mechanical seal. According to different situations and user requirements for cooling and flushing, sealing can be selected from the case according to API682 design specifications.

4. The bearing frame is designed with three forms: air-cooled heat sink, air-cooled fan and water-cooled cavity, which can be selected by users according to the working conditions. The bearings are lubricated by oil rings splashed with thin oil from the oil tank. The oil in the oil tank is cooled by the water in the water cooling chamber, and the heat in the bearing is taken away by the cold water to ensure that the bearing is in normal working condition at any time.

5. According to the medium temperature and pressure, the support form adopts the center support and the tripod support.

ZA, ZE petrochemical process pump

Category:

TAG:

TRUSTED SERVICES

We Trusted Our Customers

24/7 SUPPORT

EXPERT TEAM

Professional R&D and production team

Technical patents

Leave your contact information to get a free product quote

Related Products

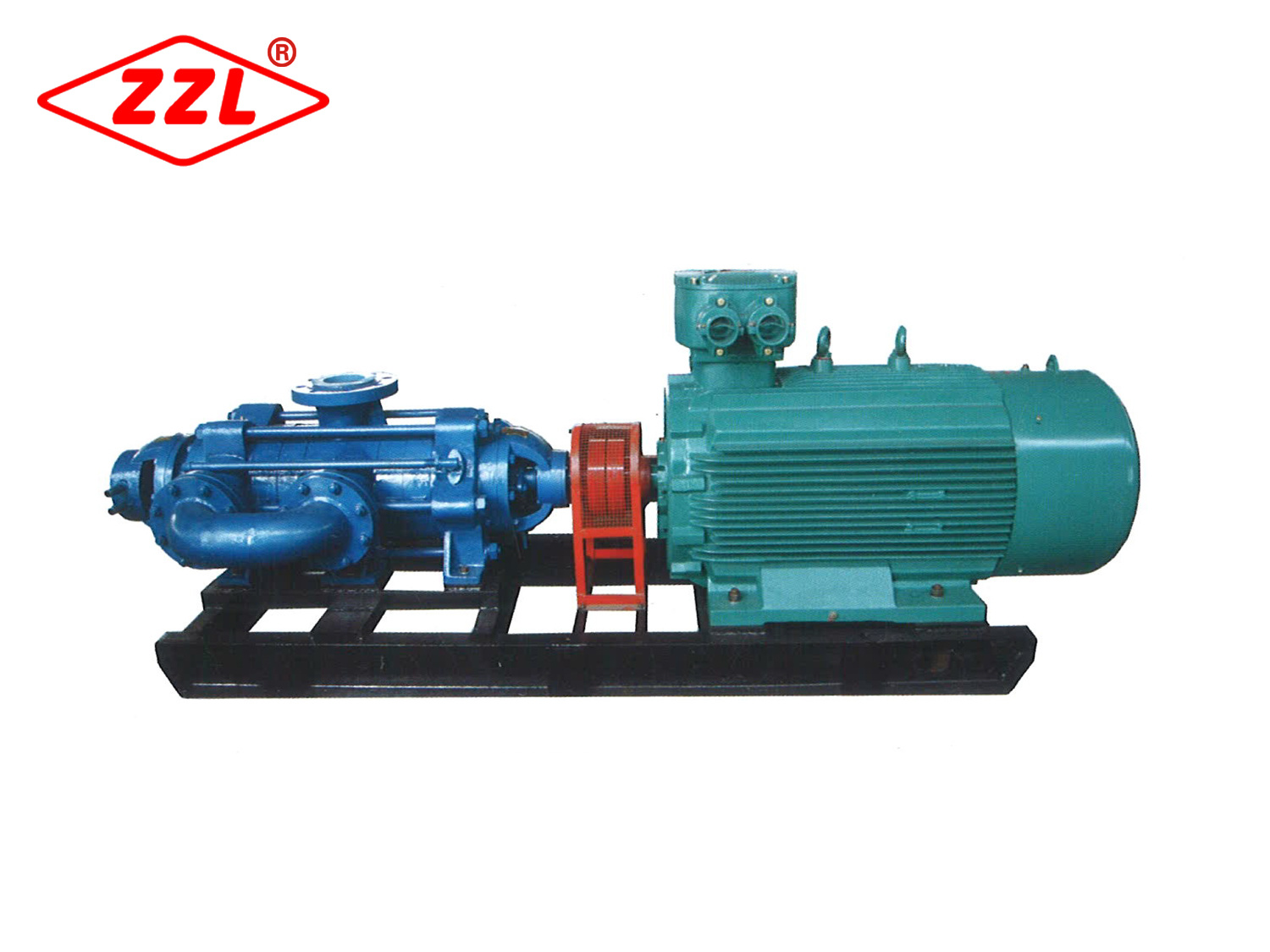

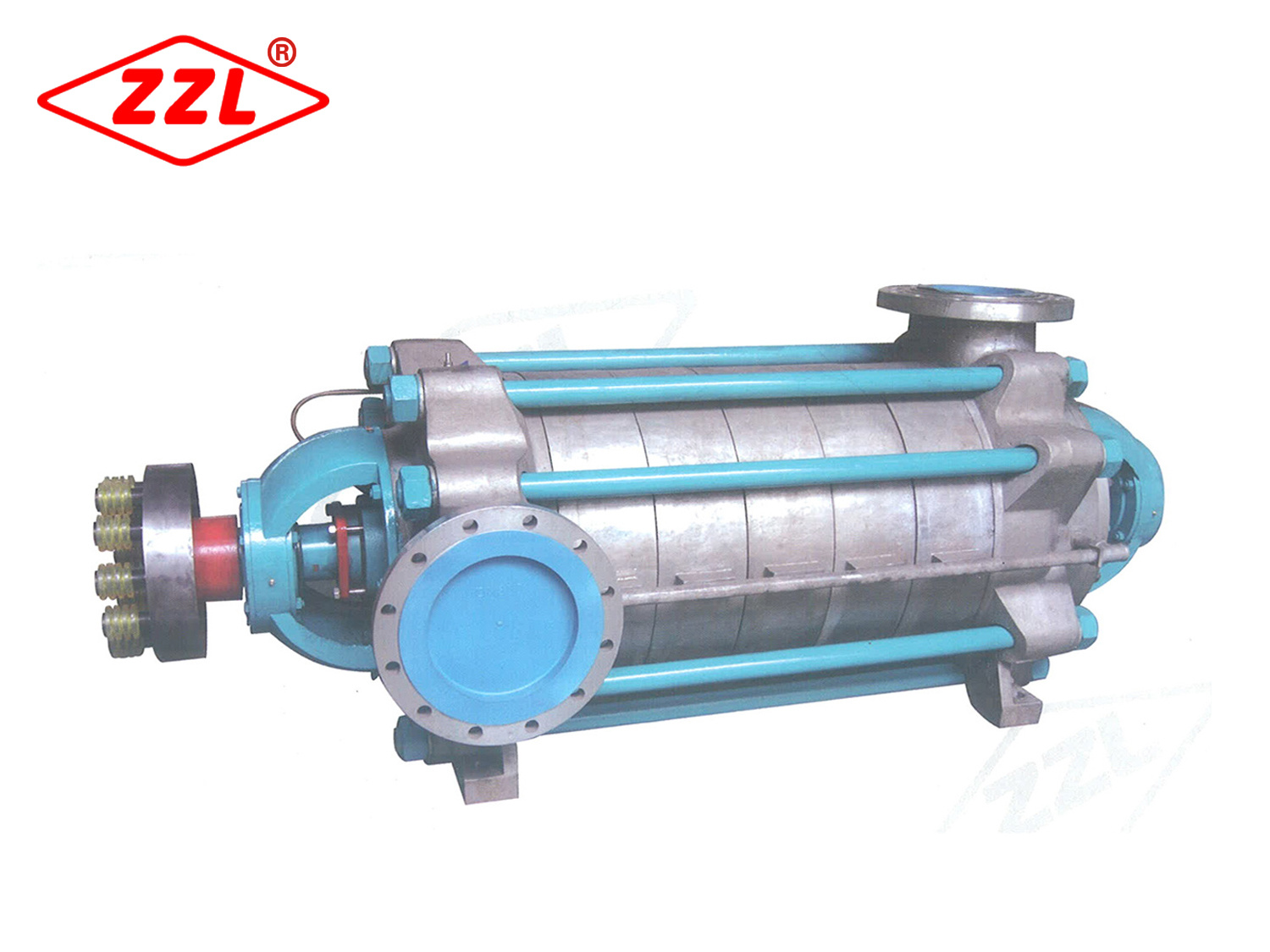

MDP, MDSP, DFP, DFSP series self-balancing multistage centrifugal pump

MDP, DFP, MDSP, DFSP self-balancing multistage centrifugal pump is a multistage

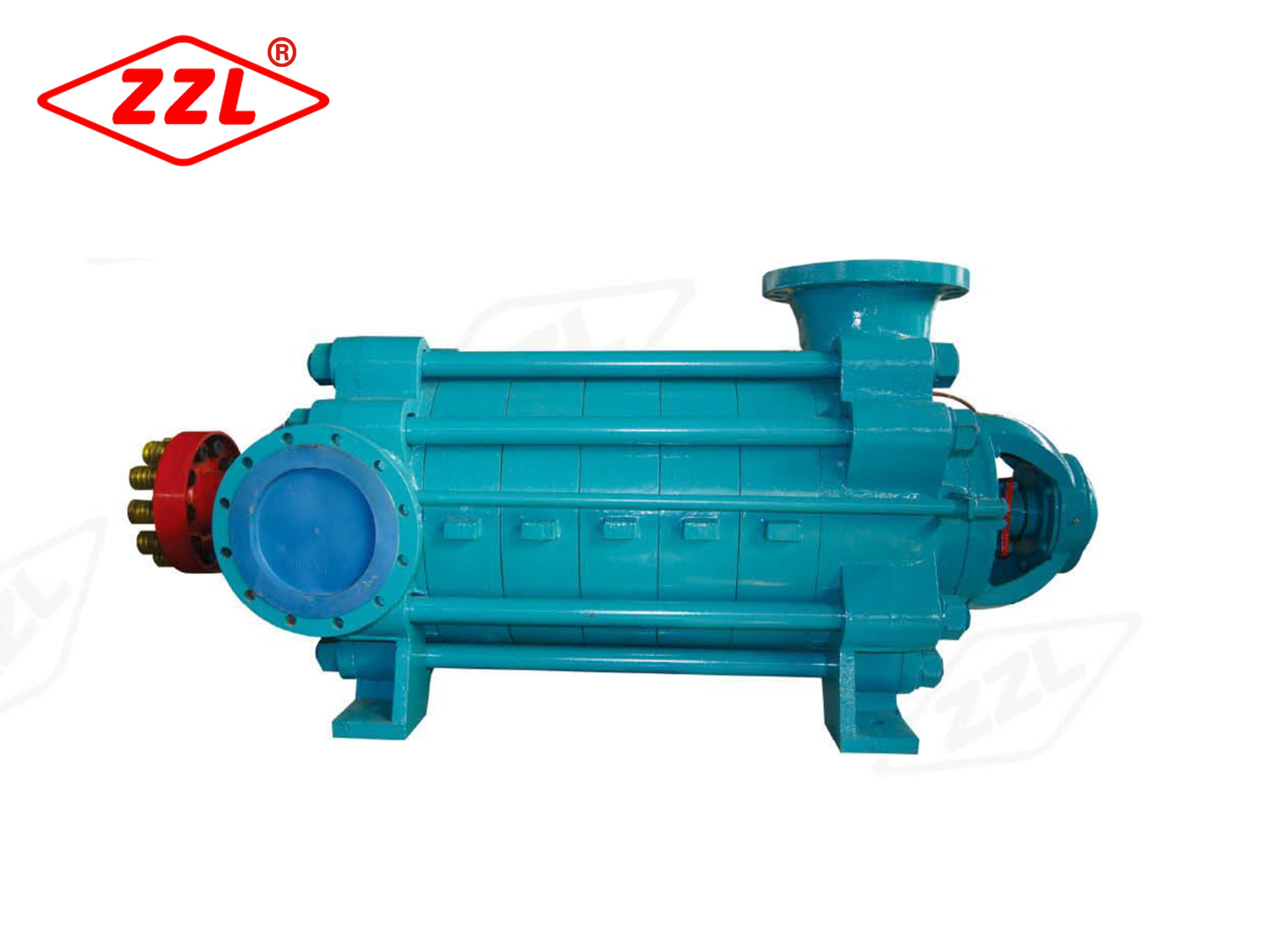

MD multistage centrifugal pump

D type coal mine with multi-stage centrifugal pump.

MD(P) self-balancing wear-resistant multistage centrifugal pump

MD(P) self-balancing wear-resistant multi-stage pump is a single-suction multi-stage structure.

DF, DFS type corrosion-resistant multistage centrifugal pump

DF-type corrosion-resistant multistage pump is a single-suction multistage segmented centrifugal pump.